Lean Six Sigma Yellow Belt Certification

315 Google reviews

961 students enrolled

315 Google reviews

961 students enrolled

Lean Six Sigma saves organizations time and money through continuous improvement. Employers therefore often pay a premium for Six Sigma trained and certified managers.

Our Lean Six Sigma Yellow Belt training teaches you the essential strategies and tools necessary for process improvement and qualifies you as a Six Sigma professional who is skilled in the fundamentals of the Lean Six Sigma Methodology.

Take your career to the next level by getting your Lean Six Sigma certification today!

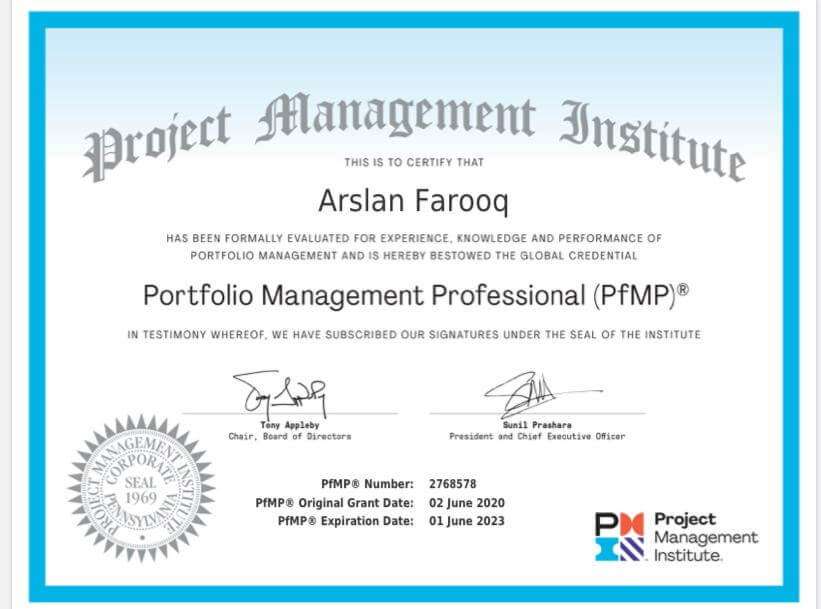

OUR ALUMNI

INSTRUCTOR LED TRAINING IN

| DATE | TIME | COURSE TYPE | PRICE |

|---|

|

No Training available |

||||

|---|---|---|---|---|

|

{{ training.From_Date }} - {{ training.To_Date }} {{ training.From_Date }} (1 Days) ({{ training.Training_Week_Type }}) ({{ training.DCount }} Days) ({{ training.Training_Week_Type }}) |

{{ training.From_Time }} - {{ training.To_Time }} |

{{ training.Currency_Type }} {{ training.Price }}.00

{{ training.Currency_Type }} {{ training.Offer_Price }}.00 valid till: {{ training.Valid_Date }} |

ENROLL NOW ENROLL NOW | |

| View More Batches View Less | ||||

Can't find convenient schedule? Let Us Know

DESCRIPTION

Achieving your Yellow Belt Certification in Lean Six Sigma (based on the IASSC standard exam) demonstrates ascertain command of Six Sigma and Lean processes and principles.

The Lean Six Sigma Yellow Belt certification preparation and training course will empower you to contribute to any continuous improvement (CI) initiative.

During the course you will learn both techniques and strategies and how to put them into practice using a range of activities and case studies.

The tools you master will prepare you for the exam, and empower you to support continuous improvement projects in your workplace. Lean Six Sigma is the most highly regarded CI and Management System ever developed - Yellow Belt Certification is your ticket to enter the world of CI with credibility, respect and ability.

The training course provides comprehensive training and exam preparation to achieve Yellow Belt Certification with the International Association of Six Sigma Certification. No prior knowledge of Lean Six Sigma is necessary to participate in this course.

Who Should Attend

Those seeking to utilize Lean Six Sigma to implement cost reduction solutions, increase revenues and drive quality initiatives should attend this course. There are no prerequisites to take this course.

Lean Six Sigma Overview

Define Phase Tools and Methods

- The DMAIC Team

- Project Types and Selection

- SIPOC Diagrams

- Project Authorization

- Communications

- Project Management Tools

Measure Phase Tools and Methods

- Data Collection

- Process Maps

- Basic Statistics

- Gage R&R

- Basic Measurement Systems Evaluation

Analyze Phase Tools and Methods

- Introduction to Hypothesis Testing

- Theory of Constraints

- Failure Modes and Effect Analysis

Improve Phase Tools and Methods

- Eliminating Waste

- Work Balancing

- Visual Management

- Total Productive Maintenance

- Kaizen

- 5S

- Gemba

- Plan-Do-Check-Act

- Cost Benefit Analysis

Control Phase Tools and Methods

- Standardization & Documentation

- Introduction to SPC/Control Charts

- Mistake (Error) Proofing

- Control Plans

- Become a problem solver using Six Sigma principles to maximize your performance

- Learn the strategies and tools necessary to support quality improvement initiatives

- Learn how to support improvement projects as a part of a team or conduct small projects of your own on a part-time basis

- Add the Lean Six Sigma Yellow Belt Certification to your resume

During this course, you will develop:

- Complete understanding of Six Sigma

- Ability to improve processes for enhanced product quality

- Understanding of the tactical and strategic aspects of Lean Six Sigma

- Understanding of process capability

- Skill to Define, Measure, Analyse, Improve and Control (DMAIC) processes

- Understanding of process discovery

- An accurate system of predicting outcomes, measurable and quantifiable

- Clear understanding of goals

- A highly effective methodology to improve processes drastically

- Methods to minimise variability in processes

- Capability to maximise production by fully utilising the potential of processes

- Ability to reduce waste through the identification and removal of present and potential errors

- Control over defects for their effective prevention

- Means to build strong managers and leaders

- A highly effective quality management system

- Smoother, faster and error-free processes

- Effective means to drastically increase savings through reduction in waste and improvement in processes

.png) Project Management

Project Management Custom Product

Custom Product Agile and Scrum

Agile and Scrum Business Management

Business Management Technical Training

Technical Training Quality Management

Quality Management